Vis-U-Etch Cupric Chloride Etcher Controller

Oxford V.U.E., Inc.

11711 Clark St., Ste 108

Arcadia, CA 91006

USA

ph.(626) 256-6557

fax(626) 256-6567

www.oxfordvue.com

|

TECHNOLOGY LEADER IN STATE OF THE ART CUPRIC CHLORIDE REGENERATION |

|

|

* Etcher dependent |

|

|

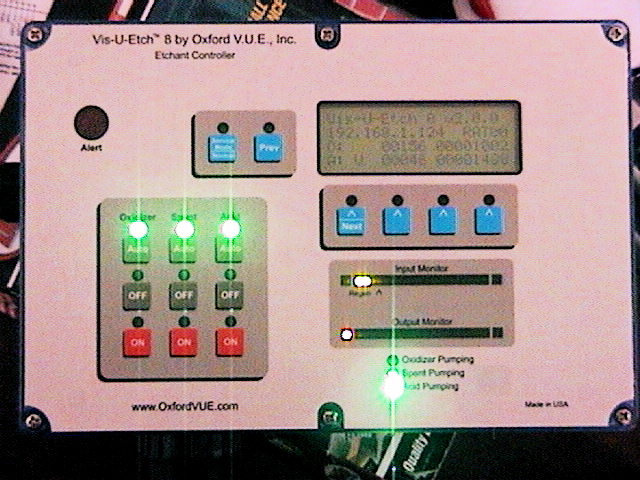

THE ELECTRONIC SECTION |

|

|

|

| Continuous reading LCD display indicates all controller functions and service modes. Sophisticated Input Chemical Failure Alarm System provides automatic shutdown when necessary. Chemical usage monitored to prevent runaway chemical adds. Flow rate history stored for SPC tracking of chemical usage. SPC function can also be remotely monitored via any computer on your LAN using your standard web browser. Easy access to all PLC functions via external pushbuttons. Simple to follow menu system allows easy interaction without consulting the owner’s manual. Valve solenoids are driven by independently fused, solid-state, zero-crossing relays. Bright panel lamps can easily be seen in well lit areas. Independent fuse protection for all necessary circuits. |

|

|

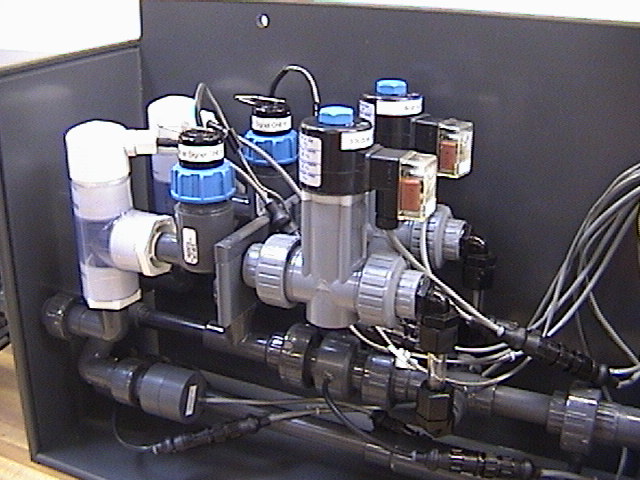

THE CHEMICAL SECTION |

|

|

|

| Glass Light Cells are immune to degradation from etchant. Glass Light Cells are made with Pyrex® glass to eliminate damage caused by thermal shock. CPVC valves with latest technology Oxford V.U.E., Inc. Aflas® valve cores ensure maximum reliability and long life. Spent valve (optional) has timer circuit in electronic section to hold valve open for a minimum of three seconds at a time to prevent hydraulic “hammering” when valve is turned off. This extends valve life significantly. All serviceable parts in the chemical section are assembled with unions. This allows five-minute replacement using no tools. Etcher can be turned on immediately after servicing eliminating costly down time. Float assemblies used for acid and oxidizer provide low level indication and are modular in design. |

|

|

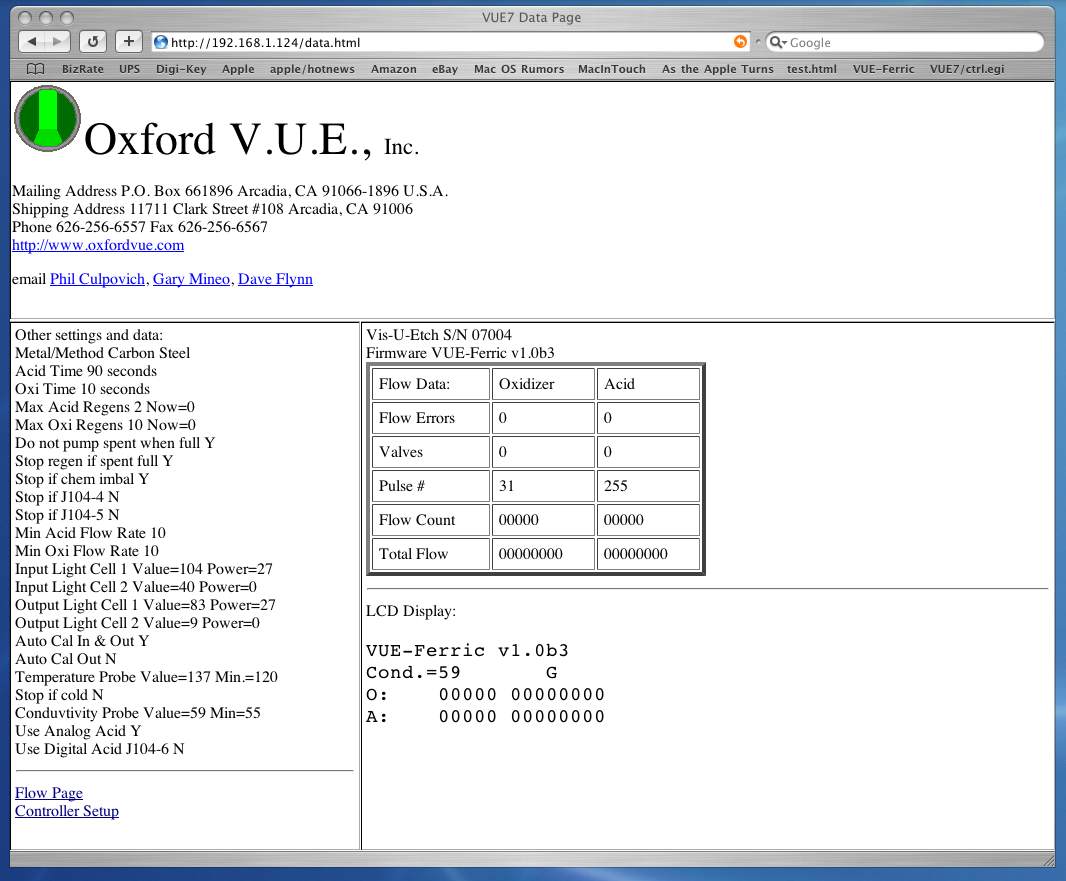

REMOTE MONITORING |

|

|

|

|

Use your web browser on a PC or MAC to monitor and adjust all

controller functions. Simply type IP address shown on the VUE 8 LCD

display in to your web browser to access the monitoring and adjustment

screens. Only three screens used for all information making this interface

extremely easy to use. Settings and history are recorded and can be sent via

e-mail to Oxford V.U.E., Inc. for diagnosis and confirmation of proper

controller operation. Does not store any confidential job data for complete

security.

|